Introduction

Forklift scales are mainly used as high-precision weighing products for dynamic weighing and measurement in factories, mines, railways, stations, ports, docks, factories, freight yards, steel, metallurgy, construction engineering, building materials, bulk material storage and transportation, etc.

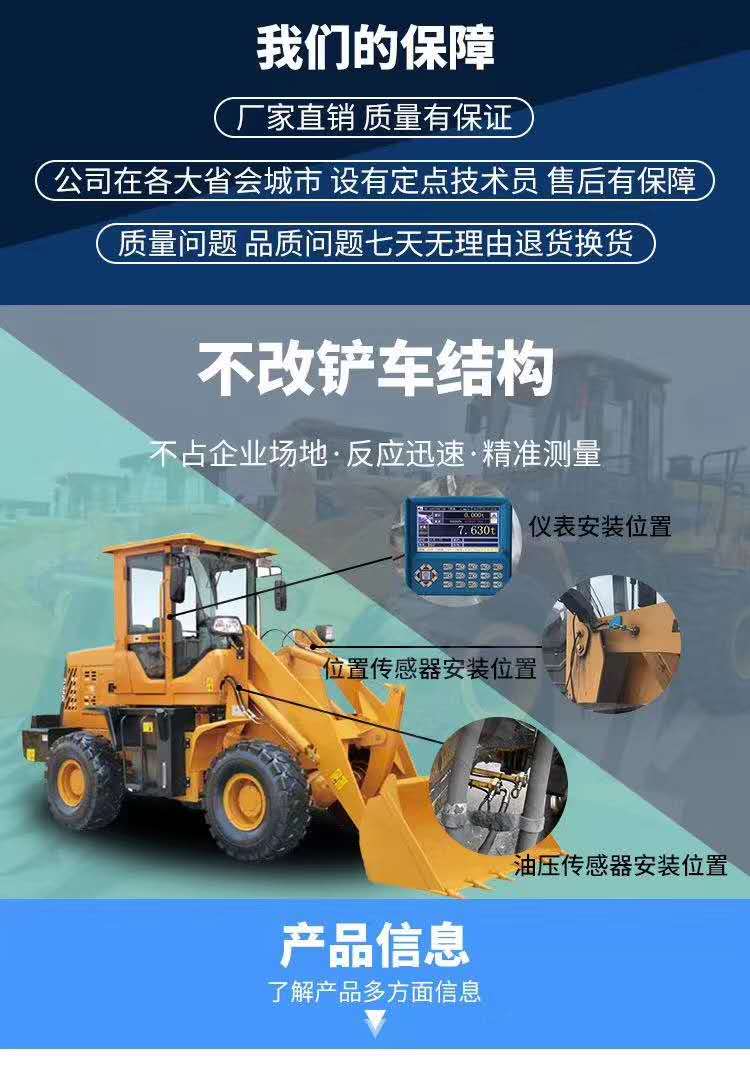

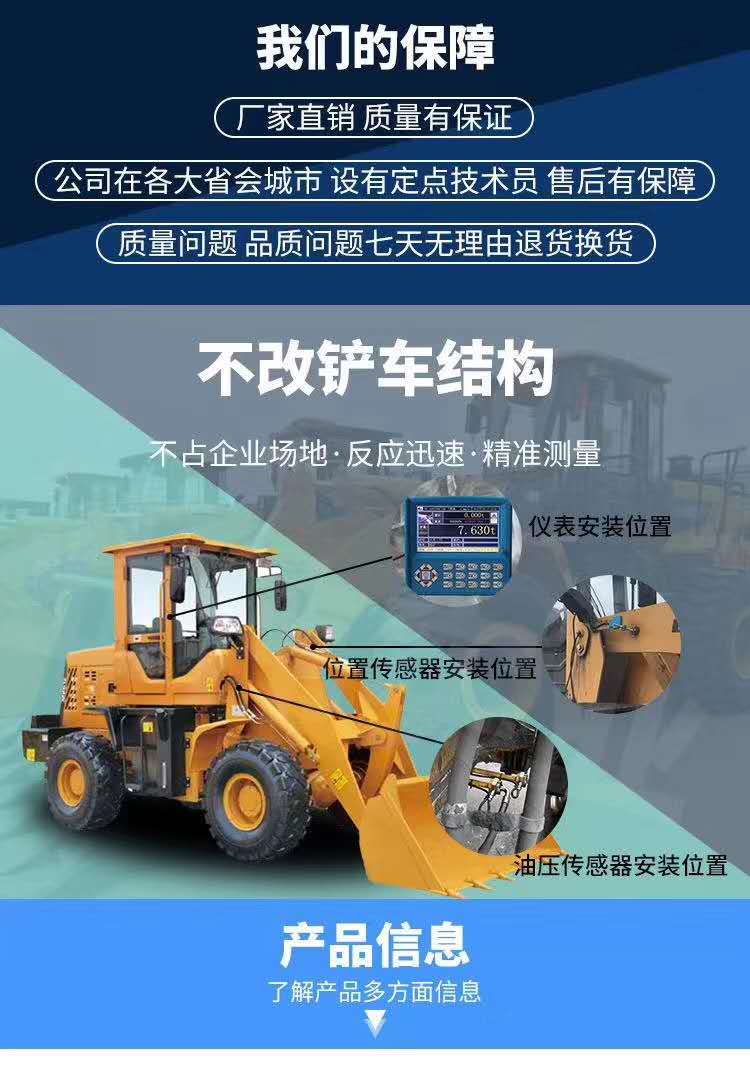

On the basis of not changing the original structure of the loader (forklift), weighing equipment is installed, and both hardware and software comply with the logistics loading workflow, improving loading and unloading efficiency and efficiency.

Customization can be made based on different brands and models of small loaders (forklifts), local specialty loaders (small forklifts), and private loaders. Solved the weighing needs of specific loaders and received unanimous praise from customers.

Working principle:

Install two sensors on the loader to collect the pressure difference of the lifting pressure cylinder piston. Use digital simulation software to convert the pressure signal into a weight signal. The data is calculated and processed by a microcomputer processor to display the weight value, and the data is printed as needed.

Dynamic measurement throughout the weighing process, with precision strictly in accordance with the regulations of the International Organization of Weights and Measures, with an error of ± 1%, suitable for various loaders both domestically and internationally

Product structure:

This product has the characteristics of good sealing, shock resistance, dust prevention, friction resistance, water resistance, anti-interference ability, and adaptability to various harsh environments.

Microcomputer display: Large screen dot matrix graphic display, capable of displaying various graphic or character contents. Featuring pinyin input for all Chinese characters, with anti glare design and clear vision under direct sunlight. The background light function ensures night work and tunnel operations. The monitor can display not only the weight and cumulative weight of materials in the tipping bucket, but also information related to weighing, such as company name, vehicle number, material type, etc. At the same time, it can display information such as the current time.

This product can meet the personalized needs of customers:

Performance evaluation can be achieved, and daily, weekly, and monthly reports can be compiled based on vehicle numbers to improve worker efficiency.

Implemented printing function, solving the problem of difficult data loading for customers to print.

The weighing time can be printed to meet the increasingly sophisticated weighing requirements of the railway bureau.

Micro computer control, full dynamic measurement, forklift does not need to stop during lifting process, simple operation, and can effectively prevent overloading and underloading.

Basic data storage and printing function for all Chinese characters and pinyin input homework

Good IP level and strong anti-interference ability, suitable for places with harsh environments and interference.

More Products