Introduction

Specially used for supporting industries such as metallurgical steel casting and casting

Maximum weighing: 240T

1、 Product Description: In order to improve the quality of steel and reasonably control manufacturing costs, metallurgical enterprises generally need to install two sets of electronic weighing systems in the process of refining and continuous casting of molten steel for online measurement. 1. The onboard ladle electronic scale is used to detect the liquid level when injecting molten steel into the ladle, and to control the amount of alloy materials added during refining to improve smelting quality. At the same time, it measures the weight of molten steel in the ladle. 2. The rotary table ladle electronic scale is used to monitor the continuously decreasing molten steel level in the ladle during continuous casting, and to control the flow rate in a timely manner. When the molten steel level approaches the slag, the tapping port is closed in a timely manner. As can be seen from the above, the operational quality of the ladle electronic scale in the continuous casting process plays a very important role in the quality of steel and improving work efficiency.

2、 Scale body structure of rotary table electronic scale

The continuous casting rotary table electronic scale is a specially designed and installed scale body on the support bracket of the steel ladle support ear seat, with one on each side and a guide frame set up for accurate alignment. It consists of proximity guide frame, final guide frame, load-bearing beam guide column, guide sleeve, anti warping plate, high temperature sensor, protective plate, etc.

3、 System characteristics

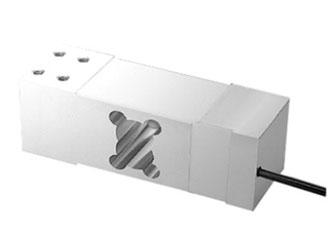

The steel ladle scale adopts a unique high-temperature type sensor and a specially designed high-temperature strain type weighing sensor. The sensor adopts a double shear, beam structure design and optimization technology. The sensor has the characteristics of good linearity, stable planar bearing capacity, strong adaptability to the environment, and can work normally at high temperatures of 350 ℃. It also has strong overload capacity, good long-term stability, and convenient installation and debugging.

The steel ladle scale adopts a unique buffering lining and pressure head to bear the force, eliminating the traditional flat plate force method, effectively offsetting the influence of lateral forces and eccentric loads on the sensor, and improving the accuracy of the sensor.

There is no need to add a guiding device. This ladle scale eliminates the traditional design of the guiding column and relies on the precise fit between the movable upper pressure head and the buffer sleeve to guide the force, preventing the scale body from being stuck or collided between the guiding column and the guiding seat due to eccentric loads and lateral forces, resulting in unstable weighing of the ladle scale.

There is no need to add a vertical buffer device, as the load-bearing point of the ladle scale cannot be made entirely in a horizontal plane, and the support seat of the ladle cannot be made absolutely horizontal. This means that the ladle scale may be subjected to force as a sensor at the moment of contact with the ladle. In this way, one of the sensors and the vertical buffer device has increased their impact force by several times, and their instantaneous force can reach more than 160 tons, which puts forward new requirements for the sensors and vertical buffer device.

The sensor used in this ladle scale has a unique design that can withstand an impact force of around 400 tons without the need for any additional vertical buffering devices.

The sealing of the scale body is good. The ladle scale adopts an integral box structure, with only one side equipped with a cover plate, which can effectively resist high temperature radiation and splashing of molten steel, and has excellent sealing performance. It is difficult to achieve this for a ladle scale with a flat plate loading method.

The thermal insulation performance of the scale body is excellent. Due to the use of a two-layer insulation board hollow structure on the side of the scale body near the ladle, it can effectively block the radiation heat of the ladle, thereby

Improve the service life of sensors and ensure product performance.

The reliable safety is achieved by eliminating the design method of flat guide columns and adopting an integral box type thick plate structure. Moreover, the scale body is directly welded to the beam to form a whole, and the possibility of the scale body overturning is almost zero.

◎ Easy installation and maintenance of the scale body

When replacing the sensor, simply open the cover plate on one side of the scale body to remove the sensor, making maintenance quite convenient.

4、 Technical performance indicators

◎ Weighing accuracy: soil O.5% FS

Weighing tonnage: 100t240t<

◎ Scale values: 20kg, 50kg, 100kg

◎ Permissible overload capacity: 200% Max

Ultimate overload capacity: 300% Max

◎ Permissible partial load: 100% Max

◎ Working temperature range: -40 ℃ to+350 ℃

More Products