Introduction

Model: 1t-30t

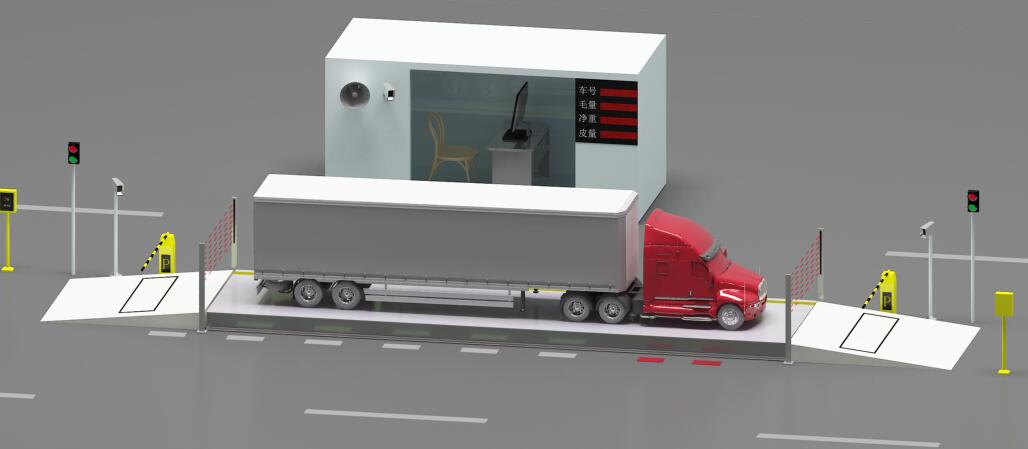

Category: Special measuring equipment for concrete mixing plants

Size: According to actual needs

Manufacturer: Dalian

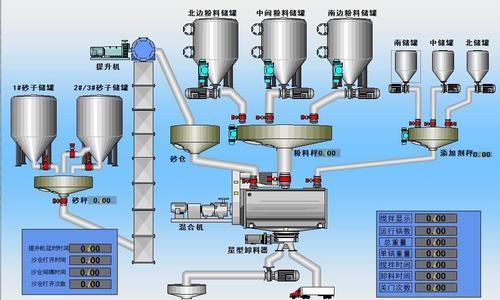

The concrete batching automatic control system (DCS-VI type) uses a programmable controller (PLC) as the control center and an industrial computer as the upper computer for monitoring and management. It automatically completes the batching, cutting, mixing, and discharge of cement, sand, stone, water, water reducing agents, and other admixtures, and can achieve online automatic detection of the moisture content of sand and stone, with precision mixing function; Compared with similar products, it has five major characteristics: high reliability of the system, accuracy of weighing, ease of operation, ease of maintenance, and strong professionalism. It can be widely used in concrete product production enterprises such as sleepers, bridges, pipe piles, and poles, as well as in mixing plants (stations) engaged in the production of commercial concrete.

major function

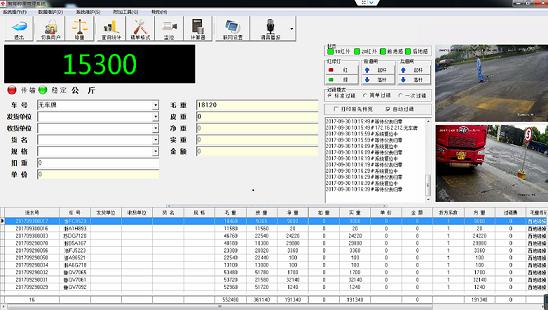

Dynamic graphics display the batching process of cement, sand, stone, water reducer, etc., automatically displaying the weighing value, theoretical value, calculated value, and batching error (%) of various batching;

Automatically adjusting the construction ratio based on the theoretical ratio of various ingredients combined with on-site data on sand and stone moisture content can achieve online detection of sand and stone moisture content;

It has manual, semi-automatic, and fully automatic functions, and can preset the cubic volume of ingredients. It can be continuously or in a single batch; Formula data can be set according to user needs, and theoretical formula numbers can be freely selected;

Has the function of correcting the impact of material cutting;

It has a pre mixing function, and the pre mixing ratio value is easy to adjust. It supports the rough and fine mixing of water and water reducing agents, thereby ensuring weighing accuracy and effectively shortening the batching cycle;

Various process parameters can be modified in real-time online;

Electronic scales, programmable controllers (PLCs), and industrial computers are protected with multi-level passwords, effectively preventing unauthorized system modifications and providing an effective means for on-site process management;

With remote communication and networking functions, users can easily connect this system to the internal equipment network of the workshop or interconnect with other automation equipment in the workshop;

Automatic alarm and fault prompt, automatic printing of construction reports, automatic raw material accumulation and data storage and query functions, providing Excel report functions;

Intelligent digital electronic scales design various parameter selection and function settings in the form of menus, allowing users to quickly complete various operations by selecting them; This scale has multiple functions such as automatic calibration, automatic zero adjustment, drift tracking, and comprehensive self verification;

Optional function: concrete slump control function; Process image monitoring function; Visual intercom function; The water tank has automatic temperature control and automatic water filling functions.

Main technical indicators

1. Ingredient accuracy:

Cement ≤ ± 1%, stone and sand ≤ ± 2%

Water reducer, water ≤ ± 1%

2. Usage environment:

Temperature: 0-40 ℃

Humidity: ≤ 85%

3. External dimensions (centimeters)

Length x width x height 130 x 95 x 125

More Products